Agitated Vessels

MOQ : 2 Tons

Agitated Vessels Specification

- Open Style

- Top manhole/opening with gasketed lid

- Wall Materials

- Stainless Steel or Mild Steel with internal polish/lining

- Connection

- Flanged, threaded or welded connections for piping and instruments

- Insulation

- Dimension (L*W*H)

- Customized as per process requirements

- Window Material

- Tempered Glass or Polycarbonate (if provided)

- Door Material

- Stainless Steel, sealed for pressure/vacuum operations

- Life Span

- 15-25 Years (depending on usage and maintenance)

- Material

- Stainless Steel (SS304, SS316), Mild Steel

- Roof Material

- SS304/SS316 or MS with suitable lining

- Thickness Of Wall Panel

- 3mm to 12mm (as per design)

- Door

- Top manhole or side entry port

- Window

- Sight glass for process observation

- Window Style

- Round/Sight glass (if provided)

- Floor Material

- Stainless Steel or Mild Steel (depending on requirement)

- Floor Load

- Designed as per vessel capacity and operational load

- Roof Dead Load

- Calculated based on agitator and equipment weight

- Roof Live Load

- As per operational requirements

- Earthquake Intensity

- Designed as per IS code/ASME standards for seismic zones

- Color

- Natural metallic finish or customized coating

- Use

- Mixing, blending, reaction, and storage in chemical, pharmaceutical, food, and beverage industries

Agitated Vessels Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 3 Tons ton Per Month

- Delivery Time

- 20 Days

- Main Domestic Market

- Maharashtra

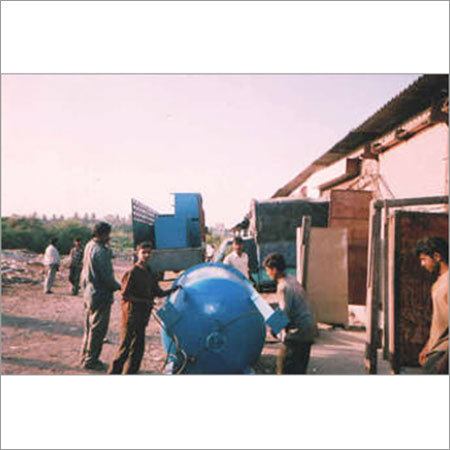

About Agitated Vessels

With healthy experience of several years and complete know-how of the steel industry, we are engaged in manufacturing Agitated Vessels. Equipped with heating and cooling external jackets, these vessels are used for controlling the temperature. These vessels are manufactured using high quality materials under the supervision of the expert professionals. Our quality inspectors check the Agitated Vessels on quality and durability parameters before offering to the clients at market leading price.

Features:

-

Long operational life

-

Maintenance free

-

Impeccable performance

"Deals only in Mumbai/Maharashtra"

Versatile Design for Varied Processes

Each agitated vessel is engineered to meet the specific demands of mixing, blending, and reaction processes. The selection of agitator types, such as anchor, turbine, or propeller, ensures effective operation for a wide span of viscosities and vessel sizes. These vessels are ideal for chemical, pharmaceutical, food, and beverage manufacturing where adaptability across process requirements is crucial.

Highly Customizable Construction

With capacities ranging from 50 to 20,000 liters and pressure ratings up to 10 kg/cm, these vessels are tailored to your process conditions. Offered in stainless steel (SS304, SS316) or mild steel with appropriate linings, you can choose among several finish options, insulation types, and mounting configurations to suit floor load and operational needs, ensuring compliance with industry standards.

Superior Safety, Sanitation, and Monitoring

These vessels are designed for safety and ease of maintenance. Features include pressure relief valves, rupture disks, and safety interlocks, as well as provisions for CIP/SIP cleaning. Instrumentation options such as temperature, pressure, and level sensors allow real-time process monitoring, and sampling ports support quality control. All designs consider operational and seismic safety for peace of mind.

FAQs of Agitated Vessels:

Q: How do I choose the appropriate agitator type for my process?

A: The suitable agitatoranchor, propeller, turbine, paddle, or customis selected based on your products viscosity, mixing intensity required, and process goals. For high-viscosity materials, anchor agitators are preferred, while propellers or turbines are efficient for low-viscosity fluids. Our team can guide you to the optimal choice based on your application specifics.Q: What materials and surface finishes are available for agitated vessels?

A: Agitated vessels are manufactured using SS304, SS316, or mild steel with options for internal polishing or specialized linings, ensuring compatibility with your process materials. Surface finishes include mirror or matt, with Ra <0.4m for pharmaceutical use, delivering both hygiene and corrosion resistance.Q: When should I opt for a jacketed vessel and what are the benefits?

A: A jacketed vessel should be selected when your process requires heating or cooling. Jackets facilitate precise thermal control, improving reaction efficiency by maintaining desired temperatures between ambient and 300C. Single, double, or triple jacket options are customized as per operational needs.Q: Where can instrumentation and sampling ports be incorporated?

A: Temperature, pressure, and level sensors, as well as sampling ports, can be integrated on request at specified vessel locations. This supports accurate process monitoring, quality control, and compliance with regulatory standards. Placement and configuration are customized based on your processing requirements.Q: What cleaning provisions are available for these agitated vessels?

A: For rigorous cleaning and sanitation, vessels can be equipped with CIP (Clean-In-Place) or SIP (Sterilize-In-Place) systems. These provisions enable automated, thorough cleaning without disassembly, meeting hygiene norms in pharmaceutical, food, and chemical industries.Q: How are safety and process security ensured in these vessels?

A: Safety features include pressure relief valves, rupture disks, safety interlocks, and robust design as per ASME and IS seismic standards. These measures protect against overpressure, equipment failure, and external hazards, ensuring reliable and secure operation.Q: Can the vessels be customized for my facilitys space or operational requirements?

A: Yes, vessels are tailored for vertical, horizontal, or skid-mounted installation and offer customizable dimensions, connections, insulation, and color/finish. Each unit is built to fit your floor load, workflow, and regulatory needs while maintaining long operational life (15-25 years).

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

UNIQUE ENGINEERING WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry